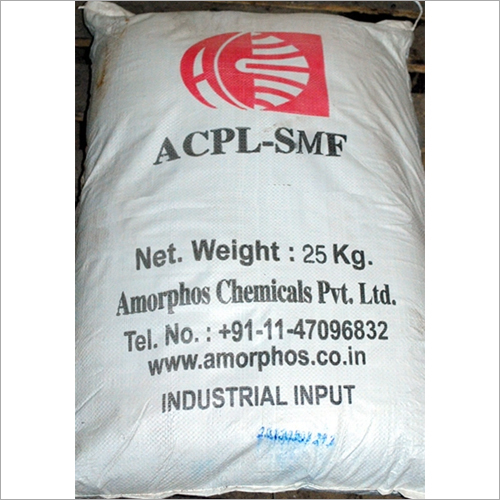

SMF POWDER

100 INR/Kilograms

Product Details:

- Chemical Name SMF POWDER

- Feature Good Quality

- Purity(%) High

- Click to View more

X

SMF POWDER Price And Quantity

- 500 Kilograms

- 100 INR/Kilograms

SMF POWDER Product Specifications

- High

- Good Quality

- SMF POWDER

SMF POWDER Trade Information

- 1000 Kilograms Per Day

- 2-3 Days

Product Description

Wax emulsion is a water-based mixture of finely dispersed wax particles in a stable liquid form. It is widely used in various industries for its versatile properties and applications. The emulsion consists of waxes, such as paraffin or polyethylene wax, and an emulsifying agent that helps stabilize the wax particles in water.

Frequently asked questions:

Q: What is Wax Emulsion used for?

A: Wax emulsion finds numerous applications across different industries. It is commonly used as a surface coating, providing a protective barrier and imparting glossiness to various materials. In the paper industry, it is used to enhance paper surface properties like water resistance and printability. Additionally, wax emulsions are used in paints, inks, textiles, and polishes to improve performance and appearance.

Q: How is Wax Emulsion made?

A: The process of making wax emulsion involves blending molten wax with water containing an emulsifying agent. The mixture is then homogenized to break down the wax into tiny particles, which disperse evenly in water. The emulsifying agent helps stabilize the wax particles and prevent them from re-agglomerating, ensuring a stable and consistent emulsion.

Q: Is Wax Emulsion environmentally friendly?

A: Wax emulsions are generally considered environmentally friendly because they are water-based and contain minimal to no volatile organic compounds (VOCs). They have a low impact on air quality and contribute to reducing solvent emissions compared to solvent-based wax products.

Q: Can Wax Emulsion be applied to all surfaces?

A: Wax emulsions are compatible with various surfaces, including paper, wood, metal, and textiles. However, the suitability of the emulsion depends on the specific surface properties and the intended application. It is essential to conduct compatibility tests before large-scale application to ensure proper adhesion and performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Dispersing Agent ' category

Mumbai

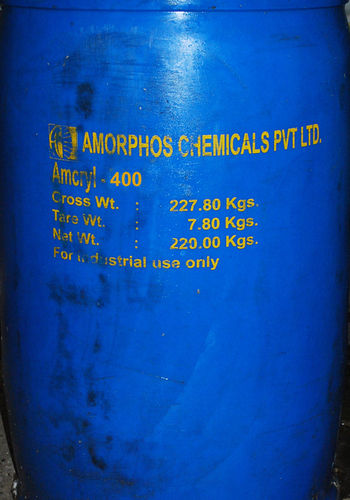

Amorphos Chemicals Pvt.

Ltd

Office No. 110, Swastik

Plaza,

Near Voltas co. Pokharan

Road No. 2

Subhash Nagar, Thanne

(West)-400601

(Maharashtra)

Contact No: 9819339351,

022-40241108

Chennai

Amorphos Chemicals Pvt.

Ltd

4/9, Circular Road,

United India colony

Kodambakkam,

Chennai-600024

(Tamil Nadu)

Contact No: 09841019941,

09486866314